Managing overspray when using airless sprayers

Experienced paint contractors will tell you airless sprayers are essential tools that provide better and more uniform coverage while significantly reducing the time required to complete jobs. They will also tell you that overspray, the airborne paint material that doesn’t adhere to the target, is inherent to the process. Overspray is, indeed, a by-product of spraying—and there are ways to minimize and control it.

Experienced paint contractors will tell you airless sprayers are essential tools that provide better and more uniform coverage while significantly reducing the time required to complete jobs. They will also tell you that overspray, the airborne paint material that doesn’t adhere to the target, is inherent to the process. Overspray is, indeed, a by-product of spraying—and there are ways to minimize and control it.

When it comes to overspray, less is always more. Less overspray means more paint gets applied to the intended surface, saving you money on material. It also means less time needs to be spent on prep and cleanup, leaving more time for productive painting. And less overspray also allows sprayers to be used for jobs not normally considered conducive to spraying, like near vehicles or property that must remain untouched by paint—or on breezy days, or when sharing spaces with other contractors.

TECHNIQUE

First and foremost, reducing overspray starts with technique. Holding the gun approximately 12″ from the substrate and parallel to the surface at all times is essential. It’s also important to understand how to adjust the pressure correctly. A common misstep is to set the sprayer to maximum pressure and start the job. The best method is to start at a lower pressure and slowly dial it up until the spray pattern is free of tails and holidays.

TECHNOLOGY

TECHNOLOGY

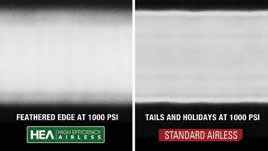

Spraying at low pressure helps to minimize overspray while reducing wear and tear on the pump and spray tip. Fairly new to the market are high-efficiency airless (HEA) tips. They can spray coatings at 1000 PSI with the same flow and production levels as standard airless tips—with up to 55% less overspray. Airless HEA tips can save as much as 35% in paint consumption and they give the operator more control and a softer fan pattern and feathered edges for a consistent finish.

ACCESSORIES

Overspray can also be controlled with physical barriers, like cardboard or metal spray shields held in position to protect adjacent surfaces. Spray guides are accessories that attach to an airless spray gun with an extension, helping control overspray by providing a backdrop to catch the spray pattern. This is especially useful at the top or bottom of a wall, when the gun is not being held perpendicular to the wall, or at the top of a fence to catch the excess spray pattern. Spray guides also make it possible to spray and cut-in simultaneously—without masking.

Spray rollers are spray tips and rollers combined into one accessory. Providing the speed of airless and the finish of a roller, they essentially allow spraying and rolling at the same time. The tip sprays the paint and the roller captures almost all the overspray and applies it to the surface being painted. They can be used on any flat, porous surface, or nonporous surfaces like walls, Sheetrock, stucco or concrete block.

Extensions and reach tools help to minimize overspray by maximizing control when working at heights. Available in lengths of 5″ to 6,’ they serve to extend your arm so you can maintain proper technique while spraying hard-to-reach areas. They can also reduce the need for ladders and scaffolding for a safer jobsite.

Anyone who’s been in this business for any amount of time knows paint sprayers are essential business tools. They make it possible to complete more jobs in less time, and with better results. By managing overspray on the jobsite, you can extend those benefits even further and grow your bottom line.

_______________________________________________________________________________________-

Chris Noto is the director of professional products at Titan. He has been in the painting industry for 26 years in sales, training and product development functions.

Chris Noto is the director of professional products at Titan. He has been in the painting industry for 26 years in sales, training and product development functions.