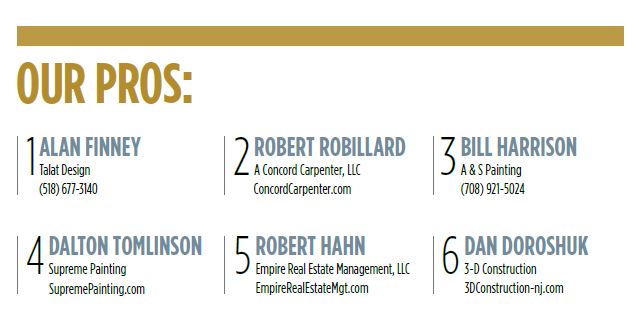

PRO PICKS: Six pros on their adhesive picks for a variety of job types

When you’re working on a renovation or construction project, adhesives matter. Whether you’re gluing wood, setting tile, laying floors, attaching crown molding … the adhesive you pick is an important choice.

When you’re working on a renovation or construction project, adhesives matter. Whether you’re gluing wood, setting tile, laying floors, attaching crown molding … the adhesive you pick is an important choice.

We asked six pros about their favorite adhesives—and what they like about them.

Here’s what they had to say

1 ALAN FINNEY: Residential renovations and construction is the name of the game for Alan Finney of Talat Design, based in upstate New York.

1 ALAN FINNEY: Residential renovations and construction is the name of the game for Alan Finney of Talat Design, based in upstate New York.

Talat, named after Finney and each of his four children, has been around for more than 30 years. With a diverse range of job types, Finney needs adhesives for a variety of different applications, including assembling stair components, constructing headers, and even laying tile.

“Depending on the job type, you need different products,” he says.

Titebond III Ultimate Wood Glue, Finney says, is an ideal pick when working with wood products.

“It’s absorbent,” he says, “and of the major glues, it probably has the most holding potential— around 4000 PSI.” (Titebond’s other wood glues have PSIs above 3600.)

“Wood glue is great for bonding two pieces of wood, but it doesn’t work as well when you have different substrates,” Finney adds. “Gorilla Glue is a really good bonding agent between dissimilar substrates.”

A drawback of the Gorilla Glue for Finney, however, is the cleanup—acetone is required, whereas typical wood glues are water based and can be cleaned up with water until they set.

And for a construction adhesive—particularly for installing subfloor to floor joists—Finney likes Loctite PL 400 Subfloor All Weather. The product boasts superior bonding capabilities and performs in extreme temperatures—from 18° F to 120° F. The formula also complies with state and federal VOC regulations.

2 ROBERT ROBILLARD: With 21 years in the construction and remodeling business, Robert Robillard, who owns A Concord Carpenter, LLC in Concord, MA, has worked with a number of adhesives. Robillard, who also runs a web site where he provides education and reviews products and tools, says that in his work, adhesives play a role with a variety of surfaces.

“Because we’re remodelers, we dabble in every facet [of construction], so we end up using a whole lot of adhesives,” he says.

What are a couple of his go-tos?

For built-in carpentry projects, crown molding and other woodwork, Robillard likes Titebond III Ultimate Wood Glue, which is known for its strength, open time (10 minutes), and its ability to be applied in lower temperatures. Robillard also likes that it’s waterproof.

Another favorite adhesive, he says, is West System’s 105 Epoxy Resin. This product, which mixes with West System hardeners for different applications, is designed to bond with wood fiber, fiberglass and more.

Robillard likes it for exterior repairs—for example, to fill the seam of a wood patch. When cured, the epoxy can be sanded and shaped and, Robillard notes, it’s superior to other options.

“A lot of guys use wood fillers and putties,” he says. “But those don’t last.”

3 BILL HARRISON: As a painter, Bill Harrison learned the hard way what happens when carpenters don’t use painter’s caulk.

“I did a whole bathroom one time and didn’t realize they hadn’t used painter’s caulk,” says Harrison of A & S Painting in Lansing, IL. “That was a lesson learned very fast.”

His pick for a painter’s caulk? DAP’s ALEX Painter’s Acrylic Latex Caulk. “I buy it by the case,” he says.

For other caulk needs, Harrison turns to ALEX PLUS All-Purpose Acrylic Latex Caulk Plus Silicone, which he says provides a smooth look whether he’s doing an interior or exterior project, and with multiple colors, the aesthetic appeal is hard to beat.

“I use white most of the time, but I’ve used them all,” says Harrison. “I did a cedar job once where I used the cedar tan caulk. The owner couldn’t get over how much better it looked.”

Another perk of the DAP products? They dry in 20 minutes, Harrison says, which is really useful for a painter who has to do both the caulking and the painting on a job.

4 DALTON TOMLINSON: Dalton Tomlinson started Supreme Painting in 1985. The company, based in Fort Worth, TX, handles a variety of residential and commercial jobs. For Tomlinson, a good adhesive comes in handy for interior trim like adding baseboards or crown molding.

“The adhesive I use the most of is Gorilla Glue,” he says. “If it’s new wood, I almost always use Gorilla Glue.”

Known for its strength, Gorilla Glue is a polyurethane formula that is waterproof and rated for indoor and outdoor use.

“It’s extremely strong,” Tomlinson notes. “If you pull apart two pieces of wood bonded by Gorilla Glue, you would probably break the wood before you broke that bond. So when you set it, you want to make sure it’s set in the right place.”

5 ROBERT HAHN: With more than 550 properties to maintain, Robert Hahn of Empire Real Estate Management, LLC in Latham, NY, is all about finding products that work.

“Liquid Nails Fuze*It is my go-to adhesive for almost everything,” he says. “When I put something up with it, it adheres fast and it stays up. That lets us keep moving forward with other parts of a project and, as they say, time is money.”

In addition to performance, Hahn is a fan of how easy Fuze*It is to use.

“Other adhesives were almost impossible to get out of the tube,” recalls Hahn. “But this stuff is the easiest thing in the world to use. Nobody’s fighting with the caulk gun anymore.”

He adds, “I have so much to do in a day, so any product that makes my job and life easier, I’m all about it—even if it is a few more dollars. Fuze*It is one of those products that’s totally worth it. I know it’s going to work and I don’t spend a minute worrying about whether I’ll have to go back and do it again.”

6 DAN DOROSHUK: With 15 years in business, Dan Doroshuk knows the value of a good adhesive. “I buy it by the case,” says the owner of 3-D Construction in Millville, NJ.

For a variety of tasks on both residential and commercial projects, Doroshuk is a fan of Titebond PROvantage PRO Heavy Duty Construction Adhesive. Designed for use with multiple materials, including metals and plastics, the PROvantage product line boasts superior strength and durability, and is waterproof, too.

“We use it for everything,” he says.

In addition, Titebond’s adhesives comply with federal and state VOC regulations. And Doroshuk found Titebond offers another value-add as well. His previous adhesive was oozing.

“When it oozes, you lose a lot of the product, and that stuff is expensive,” he says. “So, while the other brand was a good adhesive, the value is definitely there with Titebond.”