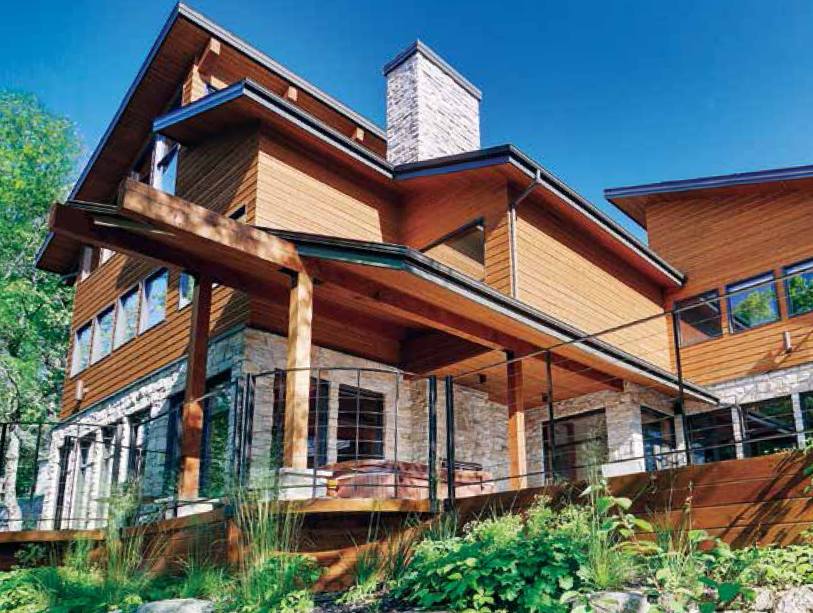

Staining siding

Wood siding is one of the most beautiful types of siding—and one of the most expensive. A quality stain job is critical to creating and preserving a high-quality look and helping homeowners avoid costly siding repairs. And the appearance and durability of any stain job depends not only on the quality of the stain product and application, but also on proper surface preparation.

Wood siding is one of the most beautiful types of siding—and one of the most expensive. A quality stain job is critical to creating and preserving a high-quality look and helping homeowners avoid costly siding repairs. And the appearance and durability of any stain job depends not only on the quality of the stain product and application, but also on proper surface preparation.

FIRST STEP: PREP

As crews ready for the upcoming spring staining season, it’s worth taking the time to review the prep process. Here are a few key points to cover to ensure outstanding stain results:

Assess areas of vulnerability. A thorough visual inspection of existing stain, including its adhesion, color and water repellency, is critical to determining the amount of prep and finish work required. Some key signs that a home needs to be refinished include:

- Water is no longer beading on the surface

- Stain is peeling, pulling or lifting from the surface

- Areas of the structure appear faded or discolored

Be sure to ask the last date the siding was refinished to help you better assess any existing deterioration.

Thoroughly clean the wood’s surface. Siding endures wind, debris and sunlight as well as mold, mildew and algae accumulation. Regardless of whether the surface is new, weathered, or has been previously coated, it is important to clean it thoroughly before beginning the staining process. If left unaddressed, the new coating may not penetrate or adhere.

While water is a great start for removing dirt and grime from the surface, a cleaning solution removes mold and mildew stains more effectively. Generously applying a combination of four ounces of trisodium phosphate (TSP), one quart of liquid bleach, and three quarts of water using a garden sprayer is an effective way to remove mold and mildew. Let the solution sit on the wood for 15 to 20 minutes while working (in sections) letting the solution dry on the surface. Pressure wash the cleaning solution from the wood with the nozzle 8″ to 12″ from the surface, then allow the wood surface to dry for 48 hours.

If rot is present on the wood surface, replace the affected boards before finishing.

Sand smooth. Sanding the wood’s surface ensures the grain of the wood is open and ready to accept the stain. Use 800-grit sanding paper and sand in the direction of the wood grain until a smooth surface is created, without blemishes, to avoid highlighting imperfections.*

CHOOSING THE RIGHT PRODUCT

Before choosing a product, it’s important to make sure you have a firm grasp of your customer’s expectations. Share the various product options and their benefits to ensure they understand why it will work best for their situation.

Key product-selection issues to consider:

- Desired aesthetics. Talk with customers about the final look they’re hoping to achieve. Review how different types of stains—solid, semi-transparent, and clear— yield different finished looks. And make sure they appreciate how the natural color of the wood will impact color choice (e.g., stains will yield a deeper color on red cedar than it will on lighter wood).

- Protection and durability. Your initial visual assessment can be extremely helpful in product selection. Look for a stain formulated to withstand the element(s) that have the greatest impact on the property.

- Working weather conditions. Often times, a wet or cold weather forecast can stand in the way of a project. Consider a product that allows you to stain in various weather conditions so you can complete the project even if the weather isn’t perfect.

MANAGE EXPECTATIONS AND RESULTS

When customers have a clear handle on what’s possible with their project, they tend to be happier with the results. But even with the most considered product selection and prep, issues can still arise when a job is done.

Checking in on a finished project will give you a jump on emerging issues, and the opportunity to offer a maintenance coat before the customer asks for it. Checking in every 18 months or so is typically safe but certain climates may warrant more frequent visits. Regardless of the time line, your customers will appreciate your commitment to their home and pride in your work. That small effort can go a long way to earn repeat business and referrals.

*WARNING! If you scrape, sand or remove old stains, you may release lead dust. LEAD IS TOXIC. Contact the National Lead Information Hotline at 1-800-424-LEAD, or log on to EPA.gov/lead to scrub the surface with a hard-bristle brush to avoid

_______________________________________________________________________________________

Vanessa Manz is a senior marketing manager and leads the strategy for professional wood-care products and brands at PPG Paints. She has 20 years of experience in strategic marketing, brand management, and new-product innovation. Backed by PPG’s global expertise, PPG’s wood-care portfolio—including OLYMPIC stains and PPG ProLuxe wood finishes—has a history of expertise, innovation and technology that delivers on the needs of professionals.

Vanessa Manz is a senior marketing manager and leads the strategy for professional wood-care products and brands at PPG Paints. She has 20 years of experience in strategic marketing, brand management, and new-product innovation. Backed by PPG’s global expertise, PPG’s wood-care portfolio—including OLYMPIC stains and PPG ProLuxe wood finishes—has a history of expertise, innovation and technology that delivers on the needs of professionals.

________________________________________________________________________________________

MAINTENANCE MATTERS

For Zach Precise of Pro Finish Paint, LLC in Springfield, MO, the key to a happy stained-siding customer is staying on top of maintenance.

“It’s really important to pay attention to the sheen or wear. If it gets away from you, you’re setting yourself up for a lot more time on the job doing maintenance—and your customer, for a bigger bill.”

Precise, who uses two-coat PPG (formerly Sikkens) ProLuxe Cetol Log & Siding Stain, spends time at the start of each project educating customers about the need for maintenance, as well as their options.

“The first thing I tell them is that no stain—no matter how much it costs—is going to last forever,” he says. “Then I outline their choices: spend more money up front on a quality product and less on maintenance down the road, or spend less money up front and a LOT more on maintenance later.”

He adds, “Personally, I like the two-coat system. It takes a little more time up front but could last 3 — 5 years or even up to 8 years on walls without a lot of sun or weather exposure. I just go back and hit the sides that need maintenance, as needed. I’m on the customer’s property less frequently and for less time doing one wall or two as opposed to the whole house.”

_____________________________________________________________________________________

BATTLING CEDAR BLEED

Extractive bleeding (or tannin) is a common and unsightly issue on cedar-sided homes. The good news is, there are a number of effective ways to remove or hide bleeding and prevent future issues. Here are a few to consider:

- Check for water issues: Because excessive moisture is a common cause of bleeding, you want to check for, and correct, any issues that may be contributing to the problem.

- Remove loose coating: Use a scraper or wire brush to remove all loose coating.

- Remove stains: Use a mild oxalic acid or oxalic-based solution to remove bleeds.

- Rinse well: Rinse all solutions and the wood with a pressure washer.

- Dry thoroughly: Allow the siding to dry for at least 48 hours. However, if weather is not cooperating, additional dry time may be required. Do NOT cheat the dry time, as moisture can contribute to bleeding.